This weekend I started the final true woodworking steps for the desk...ie the fun part. I started by rough cutting the pine edging to length and width. Note that I didn't make any edging for the back edge because it will be up against a wall so it wouldn't be seen anyway.

After I got the edging rough cut, I started getting into paralysis by over analysis mode....to miter or not to miter that was the question. I had originally planned to miter the corners so but when I cut some scrap pieces to test the fit it didn't really seem to fit the corners exactly right. I'm still not real sure why it didn't work out right because the corners are square and my table saw was set to exactly 45degrees according to my Starrett square. At the same time I was trying to decide how to attach the edging because I didn't want any fasteners showing on the finished project. So after spending an hour or so wracking my brain and test fitting pieces I finally decided I needed a break so I went for a drive to Home Depot to pick up some wasp spray (I found wasps hibernating in the basement window) and to pick up dinner since Leslie and Braden were at Super Fun Night at the Tae Kwon Do center.

After getting back and eating dinner I decided to abandon the miter plan and just butt the ends square to get the desk done in a (somewhat) reasonable time frame. I also figured out my method of attacking the edging so it was time to get back to work.

On the ends about the only way to attach the edging would be with pocket screws so that meant I had to take the backs off the shelves to be able to get my drill into cut them. That was ok because I was planning to take it off to paint anyway, just did it a little sooner than planned. On the sides I just pre drilled counter sunk holes into the plywood frame. This seemed to hold the edging tight enough so I went with it.

Otis came down to the shop to assist. He looks like he's ready and willing to help....

But his help turned into laying right in the way as I was trying to work...just like a good shop dog should I guess.

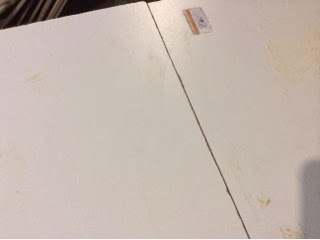

After I finally got all the edging attached I got out my WoodRiver #4 smoothing plane and flushed the edging to the surface top. This was a lot of fun. Probably the most fun thing I've done on this project. It cut the pine like butter.

This morning I went downstairs and finished the woodworking by cutting a chamfer on the top edging.

I used a chisel and file to clean up the inside corner of the desk where the router wouldn't get to.

And with that the desk is done, except for the finishing (ie the non fun part). After looking at the grain pattern of the edging I'm thinking about leaving it natural and fishing with shellac or poly to contrast against the dark brown of the base. I'll have a few days to ponder that while I get all the saw dust cleaned up fom my last couple of projects...now that's the really not fun part. Here is the before picture.

I've got just a little bit of work to do....until next time.